In this story, I’ll write about how quality control programs function and how and where they can integrate into your production workflows. Then, I’ll identify some items to consider when choosing a QC program, and I’ll share four high-level mini-reviews of quality control programs/functions from Interra Systems, Inc.; Rhozet (part of Harmonic, Inc.); Tektronix, Inc.; and Telestream, Inc. I’ll conclude by listing other vendors that offer QC systems or QC functionality for their encoding systems.

How Do I QC?

There are two basic types of QC systems: stand-alone systems, such as Interra Baton and Tektronix Cerify, and QC functionality integrated into more general encoding systems, such as Rhozet Workflow Systems and Telestream Vantage. At a high level, all QC systems work similarly; you define the tests to be performed, the notification and pass/fail options, and the files to be examined, which can be located in a local or network folder or retrieved via FTP. Beyond these similarities, however, integrated encoder/QC systems tend to weave QC functionality into various stages of the ingest/encode/deliver workflow, while stand-alone systems have well-defined pockets of functionality that are easy to access from stand-alone encoders or media asset management (MAM) systems.

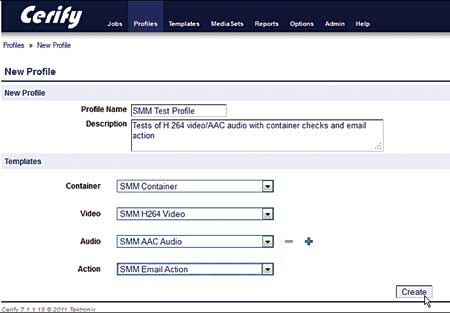

For example, Figure 1 shows the Profile creation screen from stand-alone QC program Tektronix Cerify. In the lexicon of the Cerify system, a QC job is started when you apply a profile to a set of media files. A profile contains up to four presets that define the tests to be performed and post-test actions. Like most QC systems, Cerify divides the tests into separate presets that examine the container format and audio and video quality.

For example, Figure 1 shows the Profile creation screen from stand-alone QC program Tektronix Cerify. In the lexicon of the Cerify system, a QC job is started when you apply a profile to a set of media files. A profile contains up to four presets that define the tests to be performed and post-test actions. Like most QC systems, Cerify divides the tests into separate presets that examine the container format and audio and video quality.

Post actions can include email and file transfer capabilities, so files that pass can be sent to a distribution bucket, while files that fail can be sent to a reject bucket. A typical workflow might be that your stand-alone encoding tool delivers a set of files to a watch folder that triggers a Cerify analysis. When complete, Cerify will then transfer files that pass to a folder monitored by your MAM for distribution, with rejects sent to another folder for manual examination.

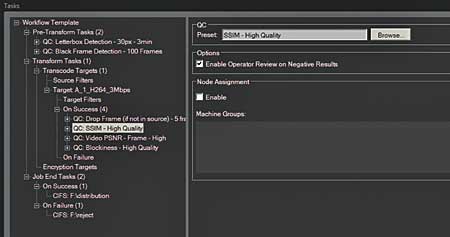

The integrated approach is shown in Figure 2, which contains a workflow from Rhozet Workflow System (WFS). In WFS-speak, a work-flow defines all the steps that occur after file ingest. You see QC functionality in two areas: pre-transform, where I’m testing for letterboxing, black frames, and confirmation that the file is 720p, and post-transform, where I’m searching for dropped frames and excessive blockiness and making sure that the files meet certain minimum values in two comparative QC tests, the structured similarity index method (SSIM) and peak signal-to-noise ratio (PSNR).

By clicking the Enable Operator Review on Negative Results check box, WFS will move any flagged files into the Pending QC tab in the WFS interface. From there, the operator can access the file, view the specific problem areas, and decide whether to pass or fail the file.

By clicking the Enable Operator Review on Negative Results check box, WFS will move any flagged files into the Pending QC tab in the WFS interface. From there, the operator can access the file, view the specific problem areas, and decide whether to pass or fail the file.

Where Do I QC?

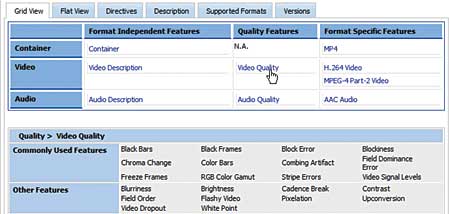

The Rhozet workflow highlights that you can deploy QC in multiple steps of your workflow, including pre-encode and post-encode. Before encoding, you can check to ensure that the file conforms to what you’re expecting so that you don’t waste encoding resources on a file that will end up in the reject bin. For example, Figure 3 shows some of the the tests that you can run from Interra Baton, including pixel aspect ratio, video format, resolution, frame rate, display aspect ratio, and scan type and scan order. Most tools, including Baton (in another group of tests) can also detect letterboxing or curtains/pillars, black frames, audio levels and silence, and a host of other issues that should kick the file out before you encode.

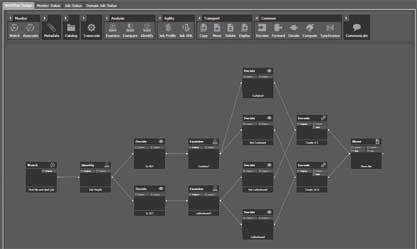

Some systems, such as Telestream Vantage, can interrogate the incoming files and make workflow decisions based upon its characteristics. It’s probably too small to see, but in the workflow shown in Figure 4, Vantage determines if the file is HD or SD and then if the file is letterboxed or curtained. Based upon these determinations, the file gets encoded using different presets.

Some systems, such as Telestream Vantage, can interrogate the incoming files and make workflow decisions based upon its characteristics. It’s probably too small to see, but in the workflow shown in Figure 4, Vantage determines if the file is HD or SD and then if the file is letterboxed or curtained. Based upon these determinations, the file gets encoded using different presets.

Post-encode, you should check the encoded file for quality and conformance. A good example of conformance types of test include those shown in Figure 3, which are the format-independent tests available in Baton. Beyond these are quality-related tests such as PSNR, SSIM, and blockiness for video and clipping and levels for audio. Finally, you should check for format-specific conformance such as profile, level, and entropy coding for H.264 video, particularly if you’re pulling together materials from disparate sources.

Post-encode, you should check the encoded file for quality and conformance. A good example of conformance types of test include those shown in Figure 3, which are the format-independent tests available in Baton. Beyond these are quality-related tests such as PSNR, SSIM, and blockiness for video and clipping and levels for audio. Finally, you should check for format-specific conformance such as profile, level, and entropy coding for H.264 video, particularly if you’re pulling together materials from disparate sources.